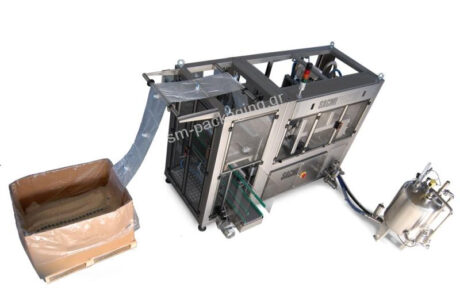

Project Description

Automatic filler for bag in box type “pre-cut continuous modular” or WEB, with the neck positioned near the side of the bags which are moving forward.

It is used for wine, water, fruit juices, various concentrates, sauces, oil, detergents ads other various liquids.

Speed:

| Bag of 1,5 lt | 820 bag per hour |

| Bag of 2 lt | 800 bag per hour |

| Bag of 3 lt | 750 bag per hour |

| Bag of 5 lt | 600 bag per hour |

| Bag of 10 lt | 450 bag per hour |

| Bag of 15 lt | 350 bag per hour |

| Bag of 20 lt | 300 bag per hour |

The production depends on the type of the product to be filled.

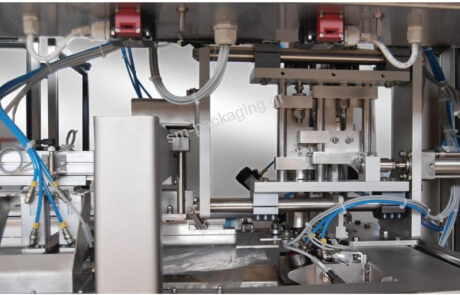

Main components of the machine:

- The machine is made of 304 peened stainless steel.

- 316 stainless steel ultra-clean valve.

- Endress+Hauser electromagnetic flow measure.

- Bag adjustable cutter.

- Bag unloading roller for manual wrapping

- Nitrogen injection after the filling process in the neck of the sack and in the cork.

- Air sucking system

- Recovering circuit CIP, which can be inserted automatically into the filling valve, fits for the steam sanitation

Product circuit and CIP that can be sterilized with vapour up to 110°

- Product circuit material and CIP that are compatible with chemical cleaning.

- Machine control PLC and format memorization (change of format in less than 5 minutes)

- Modem για υπηρεσία βίντεο

Automatic box progress

- Modem for video service

- Cap with Hepa bacteriological filters for laminar flow

- Valve and corker fit to work with the highest standard of international taps.

- 8,4” touch screen operator panel on which you can easily control all the programmable functions of the machine.

- PLC and software arranged for the automatic put of the pouch in the box in case of insertion or addition of the machine in line for the automatic wrapping.

Tecnical data

- Filling precision +/- 0.5% with Endress+Hauser magnetic flow measure

- 400 V 50 Hz input voltage

- 0,5 installed power

- 0,5 bar nitrogen pressure

- 6 Nm 3/h to 6 bar of compressed air consumption

- 24 V DC auxiliary voltage circuits