Project Description

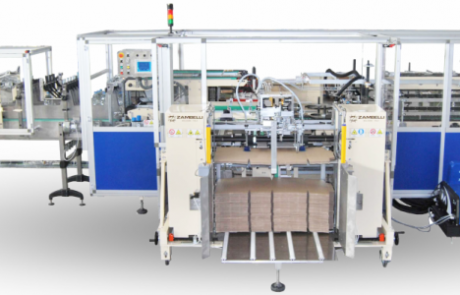

Automatic continuous motion wraparound case packer model WR40, suitable for collecting and cartoning your products, as follows:

The machine is consisting of following sections:

1. Parallel infeed: By belt in line with the outfeed, parallel to the main machine infeed conveyor, on which the products arrive at loose and random. A shuffler arranges the loose products into the required number of lanes to form the bundle.

2. Electronic product separation unit: At the end of the infeed section a continuous motion finger system fitted onto double chains and controlled by brushless motors enters among the products to form the bundle. The continuous motion of the fingers timed with the product ensures the maximum product stability when transferring the bundle onto the conveyor in the wrapping section.

Advantages: very quick size changeover time, since the bundle configuration is controlled via keyboard and by rapid gate replacement system.