Project Description

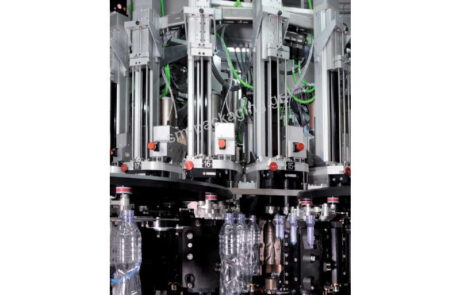

SBF ROTARY BLOW MOLDING for blowing PET preforms

The Sacmi SBF range of rotary stretch blow moulding machines represents high-end equipment able to produce more than 80,000 bottles per hour in the standard half-liter format.

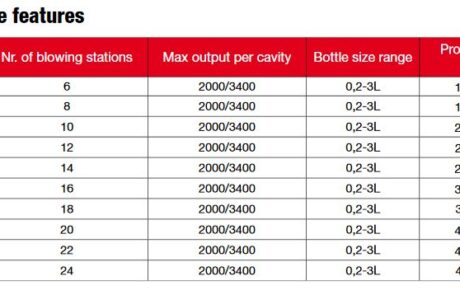

The range consists of 12 models, featuring from 6 to 30 blow moulding stations.

1 B = 2 b is the distinguishing characteristic of Sacmi SBF machines. Each machine in the range, from the smallest model with 6 cavities to the biggest with 30, can switch with the greatest ease from moulding a large bottle with 1 cavity to moulding a small one with 2.

In this way, it is possible to process twice as many small bottles, making full use of the moul ding machine’s capacity and productive potential, and of any filling machine to which it might be connected.

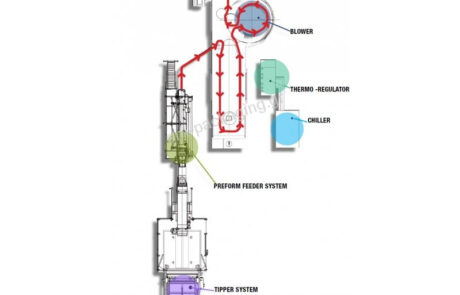

The Sacmi SBF machine has also been designed to be integrated upstream of PAM, Sacmi’s exclusive compression preform production system.

Rotary stretch blow moulder main advantages:

Main parts independently driven by brushless motors;

Few wear and tear parts (low level of noise);

- Touch screen for easy control;

- Real time monitoring of the whole stretch blowing process;

- Control and parameter setting of each single stretch blowing station;

- Possibility to stop a single stretch blowing station while keeping the machine running, in case of failure;

- Quick mould changeover (less than 3 minutes per cavity);

- Standardized blowing station for all machine types;

- Standardized IR heating modules for all machines types.